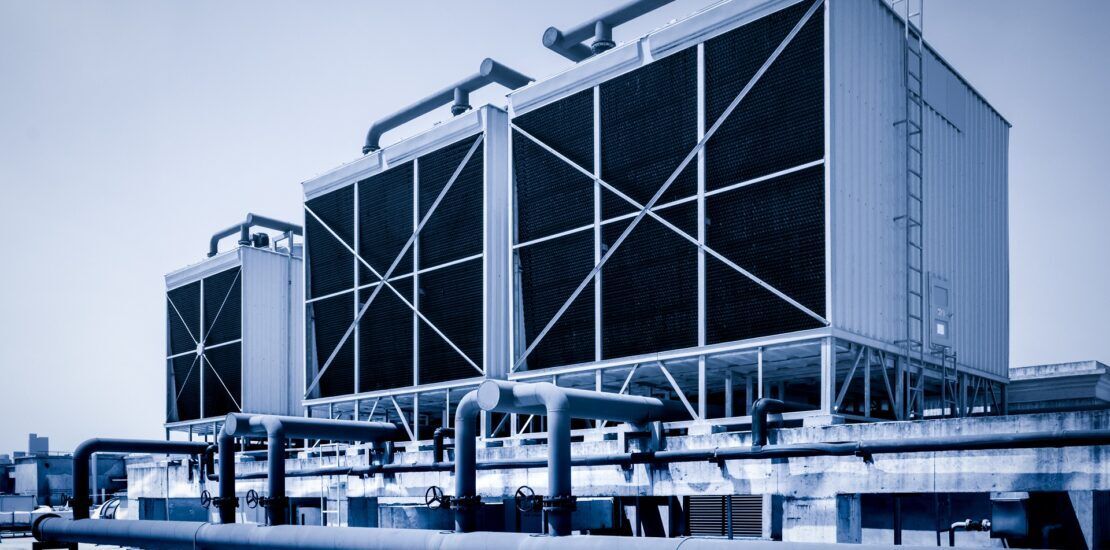

What Is a Cooling Tower Water Treatment System and How Does It Work?

Many facilities, especially industrial setups, have one or more cooling towers on-premises. Usually, these need to be paired with an adequate water treatment system to guarantee water cleanliness, efficient process, and equipment longevity. If the cooling towers are left unattended and untreated, it will result in scaling, corrosion, organic growth, foul taste and smell in water, etc. Together, these things reduce the plant’s productivity and may even result in plant downtime and costly repairs.

A water treatment system ensures that the water in the cooling towers does not get contaminated and the plumbing suffers no damage. Nonetheless, every setup of cooling towers is different and requires a tailored water treatment system.

What Is A Water Treatment System?

A cooling tower water treatment system is an assembly of technologies that help get rid of contaminants or impurities from the cooling tower and the complete plumbing associated with its storage and distribution. It includes the blowdown, circulation water, and feed water.

Factors Controlling The Cooling Tower Water Treatment System

The exact treatment plan for your system depends on several factors, like:

- The type of cooling tower on your premises. For example, open circulating, closed-loop, or once-through.

- The quality of the water feed.

- The quality requirements as recommended by the manufacturer of the cooling tower and its associated equipment.

- The chemical composition of the circulating water.

- Regulatory conditions pertaining to discharge.

- If the blowdown needs to be processed for reuse in the cooling tower or not.

- The type of heat exchanger installed in the cooling tower.

Things Controlled By A Cooling Tower Water Treatment System

The technologies that make up the cooling tower water treatment system try to control a number of things like:

- Alkalinity – to maintain proper pH balance.

- Hardness – to ensure minimal scaling.

- Sulfates – to get rid of corrosive metals.

- Iron – to maintain equipment health by ensuring iron does not combine with phosphates.

- Silica – preventing hard scale deposits.

- Chlorides – to prevent corrosion as chlorides can be corrosive to cooling tower materials to varying degrees.

- Organic Matter – to prevent the growth of microorganisms.

- TDS (Total Dissolved Solids) – necessary for preventing foaming, corrosion, and scaling.

- TSS (Total Suspended Solids) – for prohibiting the growth of biofilms in addition to corrosion and scaling.

The Working Of A Cooling Tower Water Treatment System

Water treatment systems for cooling towers are very versatile. Rest assured, there is one for every cooling tower. Following are some of the basic steps that every water treatment system will have:

- Makeup Water Intake – Every cooling tower loses water due to evaporation, bleeding, and leakage. Makeup water is what replaces this lost water and can be drawn from any source like well water, city-treated effluent, in-plant recycling of water, etc. Based on the quality of makeup water, there may or may not be a need for water treatment at this point. If there is, it will remove water hardness and balance the pH. At the same time, it will also employ measures to minimize water bleeding.

- Filtration And Ultrafiltration – The next most logical step is filtration. It involves passing water through mesh-like structures of different sizes to trap the suspended impurities and organic matter. Each successive filter is more efficient and is thus able to trap even small impurities. As the size of the contaminants decreases further, there is an option to deploy filters carrying a small electrical charge. These will hold the microscopic pollutants and prevent them from fouling up the setup.

- Water Softening – The presence of minerals in the water can make it hard and reduce the efficacy of the cooling tower. To counter this issue, water softening is required. It can be achieved by inserting lime or using a resin. The resin is charged with sodium, and as hard water passes through, resin releases the sodium and traps the minerals. Typically the resin has a high affinity for elements like magnesium and calcium.

- Adding Chemicals – Chemicals are added to change the composition of water. For example, biocides are used to remove and inhibit the growth of biofilms, phosphoric acid acts as a scale inhibitor, and bicarbonates are effective in eliminating acidity.

- Side-Stream Filtration – In case recirculated water is used in your cooling tower, there is a probability of water adulteration due to leaks and drifts. Using side-stream filtration, this can be avoided. A multimedia filtration unit is used to remove the contaminants, and it can cleanse around 10% of the water circulating through the tower anytime.

- Blowdown Treatment – In some areas, water is a scarce commodity. The cooling towers located at such facilities reuse water post-treatment. Recycling water introduces new contaminants even if it was clean before. Typically, at this stage, demineralization treatment is deployed to get rid of the common contaminants entering the water. This allows the separation of solid and liquid waste from recycled water.

When discharging water from the blowdown, it must adhere to all the regulatory specifications. The discharge from the cooling tower bleed will also have to follow the municipal discharge regulations if the effluent is being released into the nature or publicly owned treatment plants.

- Cleaning Of Cooling Tower – The complete cooling tower system, too, needs cleaning before running it. Failing to do so will contaminate the water, with the pollutants hiding inside the system itself.

Employ Only Professionals For Cooling Tower Water Treatment System

As mentioned initially, every cooling tower is unique and therefore has unique water treatment requirements. Choosing the right treatment plan may become an overwhelming decision for a facility owner. To make matters easy, it is best to ask for help from water treatment experts. A professional will never let you down as their good name, and the health of thousands of people is at stake. It is their business to help you make the correct choices in maintaining your cooling towers.

Permutrade is a professional company committed to ensuring its customers can maintain the goodness of water in their cooling towers through an optimal water treatment system. Allow us to help you make the most of yours. To schedule a consultation, click here .

Disclaimer: The information on this website and blog is for general informational purposes only and is not professional advice. We make no guarantees of accuracy or completeness. We disclaim all liability for errors, omissions, or reliance on this content. Always consult a qualified professional for specific guidance.